The SE, SE-LM and SHE type workover blowout preventers, are wellhead equipments designed to close the well. The preventers are single ram type, manual (SE or SE-LM type) or hydraulic (SHE type) operated and manual bonnet opening for ram assembly replacement.

The SE-LM type workover blowout preventers are a light weight and short version only for 2000 psi working pressure.

Depending on their ram shapes, blowout preventers perform the following operations:

- Seal the annulus between the casing on which they are mounted and the outer cylindrical surfaces of the pipes;

- Seal off the well bore when the strings of pipes, tubings or casings are extracted from the hole;

- Direct the drilling fluid from well to the mud tanks, in order to relieve the well pressure.

Using two SE or SHE type production blowout preventers, mounted back-to-back, ensure both the complete shut-off of the well bore and closing on a size of pipes. The SE, SE-LM and SHE workover blowout preventers are available with flanged end connections and studded, flanged or threaded side outlet below the ram chamber.

Outstanding feature of the SE, SE-LM and SHE blowout preventers means greater reliability, versatile application, longer service life, easier maintenance. These performances are getting through the following:

- The assembly ram design assures the "self-packing" effect that means the well pressure helps to the ram assembly sealing;

- The ram assembly design assures the extrusion of the rubber gasket towards the sealing surfaces till the free Interstices Is filled, extending the "life-time" of the seals;

- Centering guides push the drill pipes, tubing or casings to a central position by special machining practice in the ram assembly body;

- Studs and nuts for bonnet and body assembly offers easier ram change less to require special tools;

- Resilient lip type seal for stem sealing is performed because the working fluid pressure help the sealing;

- Supplementary stem sealing by soft packing injection, if is necessary;

- For high working pressure upper and lower thrust bearings offers easier ram closing.

Depending on the working environment, the SE, SE-LM and SHE type production blowout preventers, are manufactured on the following two types:

|

Manufacturing alternative |

Working environment |

|

TRIM STANDARD |

Drilling fluids based on water or oilfield products with max. temperature 212° F (100°C). |

|

TRIM NACE* |

Drilling fluids based on water or oilfield products with H2S content-conf. NACE-MR-01.75-cl.a lll-a, with max. temperature 212° F (100°C). |

Ram assembly for the SE, SE-LM and SHE workover blowout preventers

The ram assembly is available for 2 3/8", 2 7/8", 3 1/2", 4", 4 1/2", 5" , 5 1/2" pipe size

The UZW 01 and UZW 02 workover blowout preventer (double and single configuration) should be used for well servicing, coiled tubing application and complete workover operation.

Outstanding feature of the workover blowout preventer means greater reliability, light weight and short, versatile application, quick ram change, longer service life, easier maintenance.

The hydraulic workover blowout preventer is design to be operated with any oil field accumulator system and with external mechanical locks for ease of operation and safety. Hydraulic fluid passages are ported through the body eliminating the need for external piping.

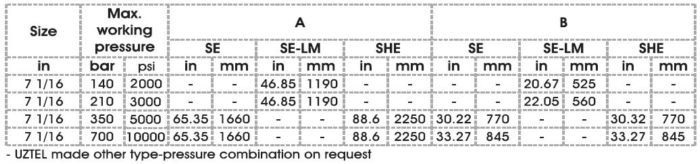

The workover blowout preventers are available with studded or flanged end connections and studded or flanged side outlets below the ram chamber. The workover blowout preventers are available for 7 1/16" 11" bore size, from 2000,3000 to 5000 psi (140,210 and 350 bar) pressure rating.